Provisions for Constructive Explosion Protection Explosion protection provisions including venting, decoupling and suppression

Provisions for constructive explosion protection

Beyond the definition of explosion protection requirements TRM Filter engineers a comprehensive constructive explosion protection of dedusting systems. We supply dedusting filter systems with certified performance to documented protection levels, consistently employing ATEX certified components. To do so we employ the following means:

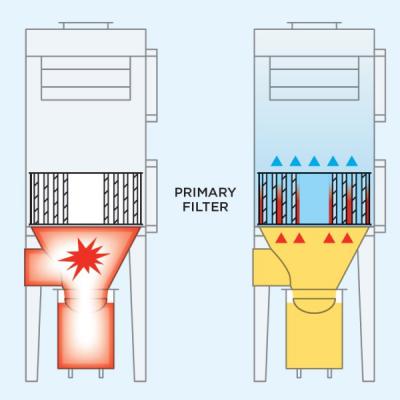

Systemic Explosion Resistance

Explosion-pressure-resistant dust collectors are built such that an explosion even of the solvent fraction in hybrid mixtures - where these are included in the intended use - can only occurr on the raw gas side. While the raw gas side is decoupled from the upstream process during filter cleaning, an explosion expands through the filter media to the clean gas side. The volume there serves to equilibrate pressure below the Pwithstand of filter housing while the flame is arrested in the filter media. This design principle is implemented with the ECR Total Pharma Dust Collector and the ECH Occupational Hygiene Dust Collector for organic dusts and hybrids. The ECB dust collector for difficult dusts is suited to handle all organic dusts in this fashion.

Explosion Resistance

Explosion-pressure-resistant dedusters are designed and built to withstand the maximal explosion pressure Pmax by virtue of their construction. An Examples is the ECO – explosion resistant dust collector.

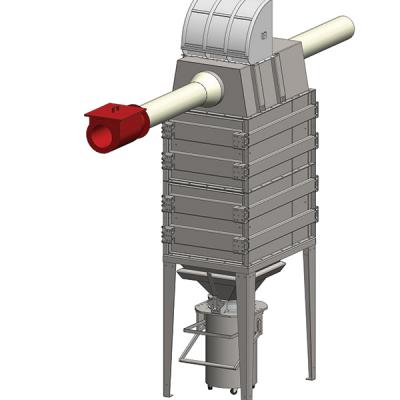

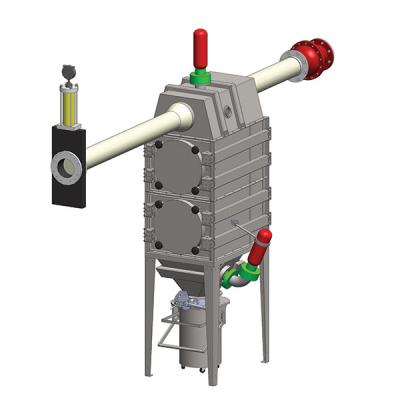

Venting

Explosion venting devices are used for either venting to the outside, f.i. in conjunction with channels or for flameless venting. In case of an explosion, pressure is released through the vent area at Pstat. It is designed to reduce the maximal pressure within the filter to a reduced pressure level Pred equal or below the mechanical resistance of the filter housing. To optimize the set of viable venting solutions TRM filter builds its dust collectors at 3 different resistance levels.

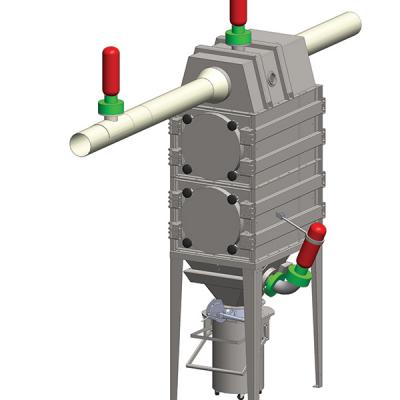

Suppression

Explosion suppression systems are used, where the toxicity of dusts requires to ascertain a closed dedusting system even in case of an explosion. TRM filter designs and builds dust collectors with these protection systems, f.i. the ECB dust collector for difficult dusts and demanding requirements.